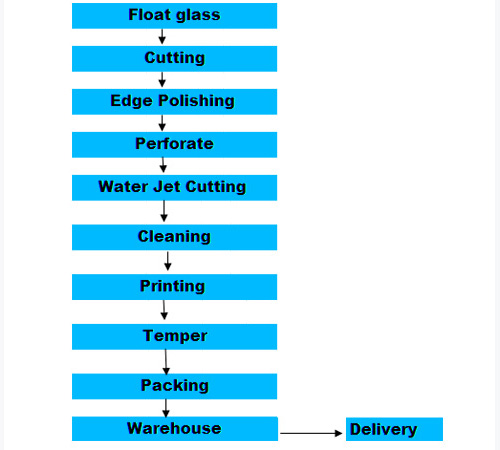

Process and Equipment

Atman is a showering specialist that has been striving to integrate sanitary supply chain to achieve win-win cooperation and be a reliable strategy partner.

Process and Equipment

Process and Equipment

Our glass are finished automatically, so there is no hand work in this process.

Mechanical automation keeps our products in high and stable quality.

In each step of processing, our staff are checking the glass very carefully to keep our glass with good quality to our customers.

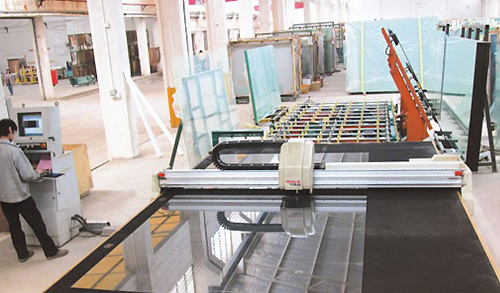

We imported advanced production line to strengthen our quality.

* Double round edge straight grinding machine x3 & Round edge grinding machine(Intermac from Italy)

* CNC center( Intermac from Italy)

* Dual-chamber furnace (TAMGLASS from Finland)

* Bottero cutting machine x2

| SHAPE | RADIUS (R~mm) | THICKNESS (mm) | GIRTH (mm) | LENGTH (mm) | |

| 3mm | 100mm-900mm | 400mm-1930mm | ||

| 4mm | 100mm-1200mm | 240mm-2300mm | |||

| 5mm | 100mm-2000mm | 240mm-2500mm | |||

| 6mm-19mm | 240mm-3600mm | ||||

| Formal curved | R≥380 | 3.2mm | 280mm-400mm | L≤1900 |

| R≥370 | 4mm | 350mm-700mm | L≤2000 | ||

| R≥370 | 5mm-6mm | 350mm-700mm | |||

| R≥490 | G≤1000 | ||||

| R≥800 | 5mm-10mm | G≤1000 | L≤2000 | ||

| R≥385 | 8mm | G≤350-700 | L≤2000 | ||

| R≥700 | 10mm | G≤900-1100 | |||

| Deep curved | R≥300 | 4mm-6mm | 330mm-450mm | L≤1980 | |

| R≥400 | 5mm-6mm | G≤350, SPL≤750 | L≤2100 | |

| R≥450 R≥600 | 8mm 10mm | G≤550, SPL≤850 | |||

| Remark: SPL=Straight Part Length (The Acutal Glass Technical is determine on the Production drawing. | |||||

The authority of technology upgrading or backward technology abandon is reserved, and depending on the actual samples!

| Bottero cutting machine*2 |

| Full-automatically on/off glasses. |

| Max speed :140m/min |

| Tolerance of diagonal ≤0.5 |

| Production capacity:900,000M2/year |

| Double round edge straight grinding machine*3 & Round edge grinding machine (Intermac from Italy) |

| The tolerance of the size is ±0.3 |

| Tolerance of diagonal ≤0.5 |

| Production capacity:600,000M2/year |

| Double flat edge straight grinding machine |

| the tolerance of the size is ±0.3 |

| Tolerance of diagonal ≤0.5 |

| Production capacity:450,000M2/year |

| CNC Center (Intermac made in Italy) |

| Milling cutter processing, Outer special shape processing, Inner special shape processing. |

| Speed: 1m—10m/min |

| Production capacity:15,000-150,000M2/year |

| Name: Cleaning room for rolling printing |

| Room pressure:+10Pa( the air can’t go into the room) |

| Cleaning :100,000 grade level |

| Production capacity:1,000,000M2/year |

Name: Dual-chamber furnace (Tamglass made in Finland, world-class advanced new technology ) |

| Part camber ≤0.3mm/300mm |

| Wholly camber ≤1.5mm/1000mm |

| Production capacity:2,300,000M2/year |

Cutting

The advanced cutting machine is controlled by the computer. lt can cut the glass into all kinds of shapes precisely.

Edge Polishing

We use the "T" shape edge polishing machine. It is connected to the cleaning equipment, and can clean the glass while polishing the flat and round edge.

Water Jet Cutting Drilling

Silkscreen Printing Drier

Tempered Glass

Sub Navigation

Promotion

NEW 4MM FULL FRAMED

ATMAN new economic 4mm full framed promotional shower enclosures shower doors like corner entry (square and rectangle shape), pivot door, two sliding doors and side panel. White painting or anodised aluminum profiles, 4mm tempered safety glass with clear or silk printing. More elegant impression with good quality but with the cheapest price in the market.

"Cambodia - Taiwan Education Program"

CTEP, a member of NGO is a charitable program aimed at helping the people of Cambodia and particularly the youth by providing education in Computing, English, and Chinese.

Contact Us

Atman GROUP

25F/B, No.445, Jiangning Road, Shanghai, 200041 China

TEL: +86 21 62994895

FAX: +86 21 62994856

View Atman GROUP in a larger map